Multi-beam Ultrasonic meters are specifically meant for custody transfer metering of crude oil and refined products.

Ultrasonic flow measurement technology utilizes transit-time of ultrasonic wave in the fluid to determine flow velocity in particular point of the flow profile. A pair of special transducers – receivers, emitting ultrasonic waves, are placed on opposite sides of flowmeter’s inner walls, one – upstream, the other - downstream. Flowmeter electronics accurately measures time between the moment when the ultrasonic wave is sent by one of the transducers and the moment when it reaches the other one. This, so called “transit time”, is then used to determine point velocity of the fluid, based on which real time flowrate can be calculated.

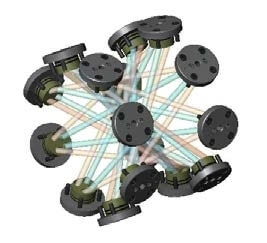

Multi-beam Ultrasonic flowmeters bear considerable number of such pairs of transducers, each providing transit-time measurements with ultra-fast scanning rate. And this results into significant amount of basic data for averaging and flowrate computation.

Calibration of Multi-beam Ultrasonic meters is performed at state-of-art and worldwide recognized calibration facilities like Euroloop in Netherlands with liquids with viscosities identical to site process conditions.

The most important advantage of Multi-beam Ultrasonic Flowmeters is that they can be proven directly by means of Bi-Directional Pipe Prover or even Small Volume Compact Piston Prover.

Certified for Custody Transfer metering Multi-beam Ultrasonic Flowmeters satisfy requirements of both international (API, OIML) as well as most of local standards.

Design details

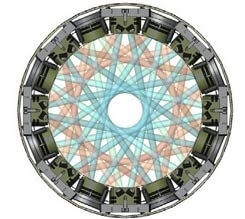

As shown on a picture below Multi-beam Ultrasonic Flowmeter bears 2 sets of transducers (each comprising 8 pcs.) located in series along the flow direction. Transducers of the first set emit 4 ultrasonic beams which are received by transducers of the other set and vice versa. This principle results into multipoint-star configuration of ultrasonic beams, which covers almost 90% of the flow profile.

Major Advantages of Multi-beam Ultrasonic Flowmeters

- Unmatchable across the industry linearity and repeatability

- Considerable number of ultrasonic beams guarantees redundancy and custody transfer accuracy of measurements in any circumstances

- Unlike other Ultrasonic meters, Multi-beam Ultrasonic Flowmeter can be directly calibrated on site by Prover with same calibrated volume, which would be required for calibration of turbine flow meter of identical size

- Multi-beam Ultrasonic Flowmeters are immune to water content in liquid hydrocarbons

- Multi-beam Ultrasonic Flowmeters are full bore and contain no obstacles for the flow. Therefore pressure drop across the meter is similar to a straight pipe spool

- Our experience proved that Multi-beam Ultrasonic Flowmeters can be even installed without upstream conditioners.