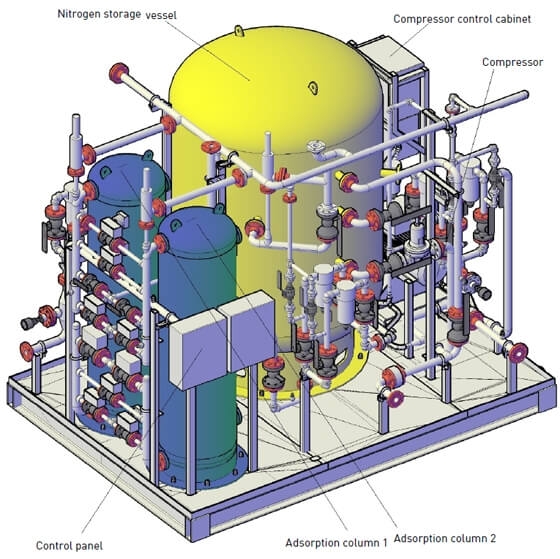

Nitrogen Generation Unit for ExxonMobil during FAT in 2011

Our nitrogen generation units are complete turnkey systems for generation of nitrogen in the field with chemical purity from 90% up to 99.999%. Nitrogen generation system capacity, required concentration and output pressure are customized individually for each project.

Nitrogen generation systems are used to extract pure nitrogen out of the atmospheric air on-site. There are various technologies used for nitrogen generation which differ by the method of obtaining nitrogen from the atmospheric air. We manufacture membrane and adsorptive nitrogen generation units.

Membrane technology

In case with Membrane based nitrogen generation technology compressed air passes through special tubular membranes which consist of a large quantity of hollow fibers. Oxygen passes freely throughout the fiber walls while nitrogen gets trapped inside the fibers and flows to the end of fiber tubes. As result compressed gaseous nitrogen is generated. Maximum purity of produced nitrogen is up to 99,95%. This is one of the most reliable technologies of nitrogen generation. The equipment has a long service life and is easy in maintenance. Membrane nitrogen system can also be used as an air compressor.

Adsorptive Nitrogen Units

In adsorptive nitrogen system air under high pressure enters the first adsorption vessel filled with adsorbent, which absorbs oxygen. As a result only nitrogen comes out of the vessel. When the first vessel adsorbent is saturated with oxygen, compressed air feed is redirected to the second similar vessel, while the first vessel gets purged from oxygen. This process is called short-cycle adsorption (SCA for short). Adsorptive nitrogen technology in comparison with membrane has higher purity – up to 99.9995%. Low energy consumption is also an advantage. But adsorptive nitrogen units require significantly more space on site and are more complicated in maintenance.