Accurate quality analysis and representative sampling are the two essential parts of any fiscal metering solution since fluid quality parameters have the same importance as quantity for fiscal operations. Our sampling and quality skids provide precise real-time measurement of all main hydrocarbon parameters, both for natural gas, crude oil and refined hydrocarbon products.

In most projects the sampling and analyzer skid forms an integral part of the metering system however we also supply sampling and analyzer skids as stand-alone units.

As per API MPMS 8.2 there are 2 main sampling methods:

Insert or In-line Automatic grab sampler for Liquid

In-line or Insertion type Automatic sampler is considered to be the most cost effective solution in cases when analyzers are not required per project specification. It’s especially true for metering systems operated on periodic basis, because maintenance can be done between batches. Insertion sampler is designed for direct mounting on the main pipeline to be sampled. The sampler stem has a flow through port where sampling mechanism will periodically grab a 1cc sample from the flow and pump it through a downward gradient small-bore pipe (to prevent water traps) into a sample receiver. Usually Automatic sampler is supplied coupled with several sampler receivers and automatic changeover mechanism which allows switching between sample receivers when one of them is already full.

Fast loop sampling system for Liquid

For applications where provision of fluid quality analyzers is mandatory Fast Loop Sampling arrangement is by right considered as the only possible solution. This statement is also true for pipeline metering systems which operate non-stop, since Fast Loop Sampling by-passes the main line and can be serviced without interrupting the ongoing metering process.

Such systems are suitable for crude oil, condensate or refined hydrocarbon products and are employed alongside most of metering systems. However, some operators have them as a stand-along units for process control of product parameters, for example, alongside large transmission pipelines.

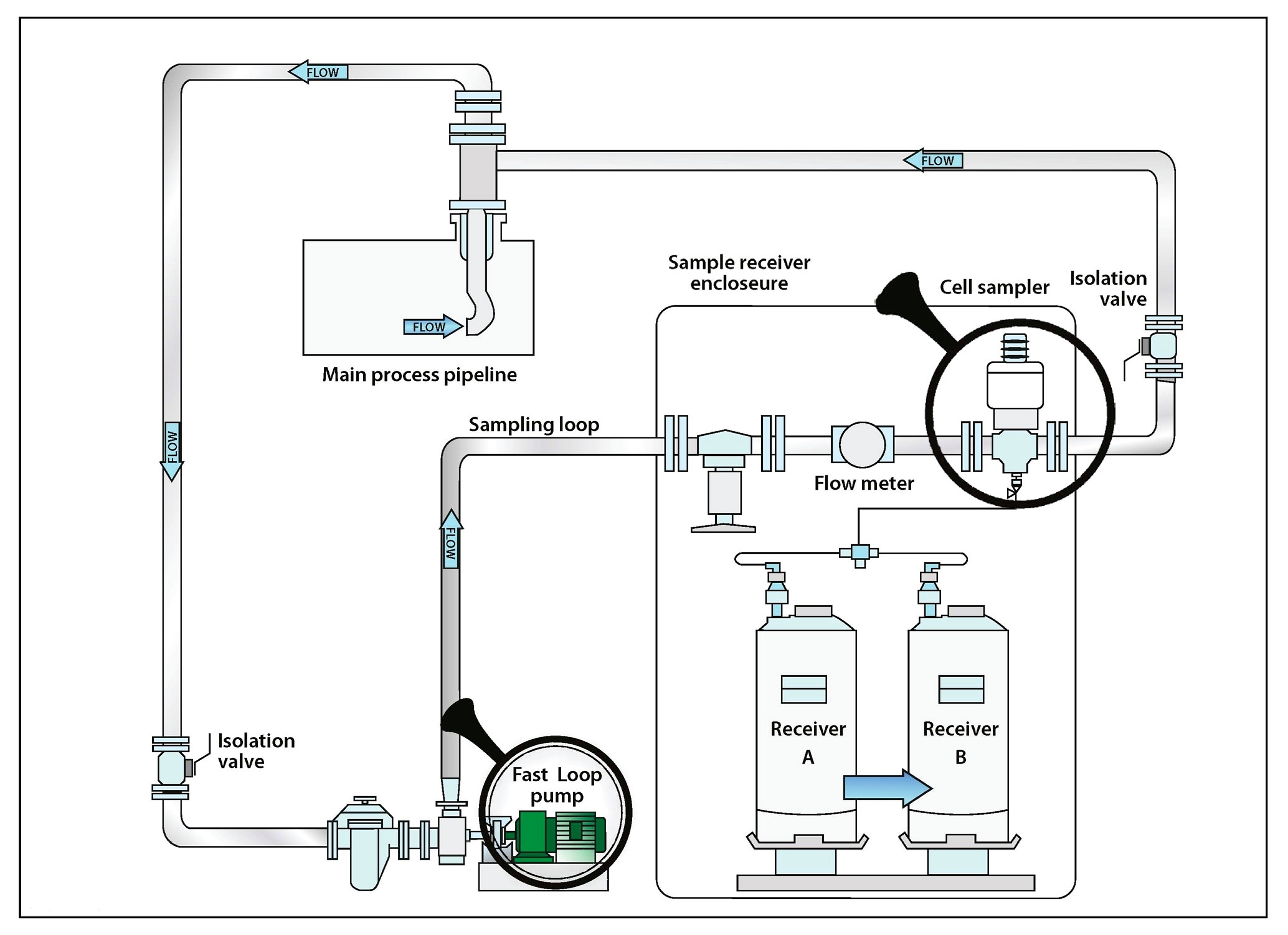

Operation of a typical fast loop liquid sampling and analyzers system is as follows:

The operating fluid (product) is extracted from the outlet or inlet header by means of a take-off probe equipped with facilities allowing withdrawing the probe from the pipeline under process conditions. Oil is pumped around a fast loop for density, water-in-oil content measurement, sample extraction etc. Sample loop flow rate is monitored. Should flow drop below a predetermined level, the flow meter signal change initiates a pause in the sample grab operation, and the fast loop pump stops. The flow through the loop is ‘trimmed’ by a manually operated globe valve fitted downstream of the sampler.

The sample probe extracts a sample under the ‘Time Proportional’ or ‘Flow Proportional’ control. Collection rates for both operating modes are selectable. It’s important to mention that for crude oil applications in order to guarantee representative samples sometimes it’s required to provide additional mixing of the fluid inside the main pipeline by means of static of power mixer.

The extracted sample is collected in a “sample receiver” which incorporates a pressure relief valve, a vacuum relief valve, level indicator and level switch. The switch is set to give an 80% full signal that stops the sample grab operation when active. In addition to the a.m. level switches digital weigh system able to communicate with Sample controller will be provided.

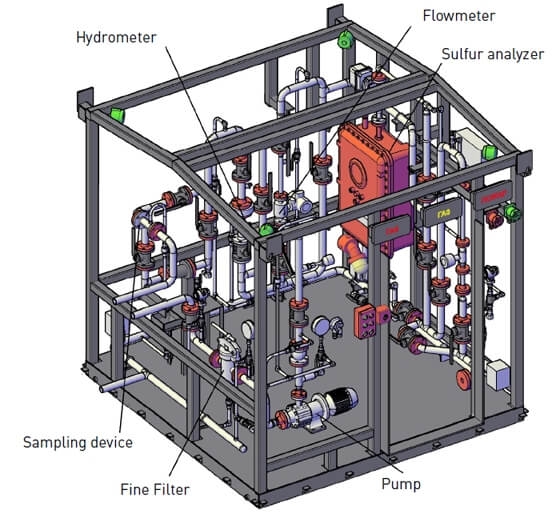

Typical Sampling and Analyzer skid depending on Project specification may comprise the following equipment:

- Basket strainers with removable filtering elements

- Fast loop pumps

- Liquid Density Meter

- Viscosity Transducer

- Water in Oil Monitor or Water-Cut Meter

- Sulfur Analyzer

- Pressure and Temperature Transmitters

- Pressure and Temperature Indicators

- Flowmeter

- Flow Control Valve

- Automatic Sampler with Sample Receivers

- Process piping, valves, drain system

- Housing or Shelter, equipped with HVAC, insulation, gas & fire protection if required

- Control & Automation is usually performed by Station Supervisory system, however it could be supplied as dedicated system

In certain cases some of the above process instrumentation units are redundant to ensure accurate readings even during maintenance services.

The fast loop components are usually mounted on a skid and housed inside heated enclosure/shelter.

Gas Sampling and Analysis packages

It’s common industry practice to perform Custody Transfer of gas basing both on volumetric and mass flowrate as well as on total energy caloric value. Composition analysis performed by gas chromatograph is essential for caloric value calculations. And therefore Gas Chromatograph is usually an essential part of any Gas Analysis system. Hydrocarbon dew point analyzer is also required for most of fiscal gas metering applications. Sometimes project specification also demands H2S, CO2 and H2O content analyzers, especially when high content of the above components in the fluid may damage downstream equipment.

Housing and Environmental Protection

Since all of the above mentioned analyzers are very sensitive and operate properly only in narrow range of process and environmental conditions we give special attention to sample conditioning and environmental protection of analysis equipment. Usually for any kind of outdoor installation all the equipment of the gas sampling and analysis package is located in special shelters/enclosure complete with explosion proof heaters, HVAC, fire and gas protection systems.