Transportation and handling of viscous products, such as crude oil, heavy fuel oil, molasses and fats is time-consuming and costly.

Once solidified inside a railway car these materials must be preheated before they can be pumped out. This results in lost time and reduced capacity of unloading terminals. This is most serious during winter in areas with extreme continental climate.

On the other hand, existing unloading systems can’t meet increasing client demands for productivity, quality, environmental awareness and safety.

Our rail tank unloading systems address all of these requirements, and guarantee that viscous product unloading process will be:

- Easy to control

- Fast and complete

- Water-free

- Emission free

- Safe

- Cost-effective.

Our patented unloading technology is based on dual circuit preheating and unloading.

Heat is transferred by the product itself without usage of hot water or steam. It means that water content in the fluid after unloading process is completed remains the same. And this is the main advantage of our technology since it preserves transferred product quality.

How it works

A certain amount of hot product (identical to the fluid inside the rail way tanks) is kept in a special starting vessel. At the initial stage of the process, hot product from this vessel is pumped into the railway tank car from the bottom, thus heating the lowest layers of the tank contents. Once the lower fluid levels are heated, they begin to transfer heat to the rest of the fluid inside the tank.

Later, to achieve more effective and rapid heat transfer, a part of the circulating hot fluid is diverted and fed into the tank through the over-head loading arm. As a result, solidified fluid inside the tank is heated simultaneously from above and below. When the fluid inside the tank becomes hot enough and its viscosity is reduced, gradually more and more fluid is drained into the receiving vessel until the whole railway tank is empty.

High viscosity fluid unloading solutions allow railway tanks containing hardened and extremely viscous hydrocarbons to be emptied within a couple of hours. Each unloading system is engineered to meet the customer’s requirements and is supplied as a “turn-key” solution.

We offer its reheating and unloading systems in 2 basic designs:

1. Single railway car Reheating and Unloading system (one unit per each railway car);

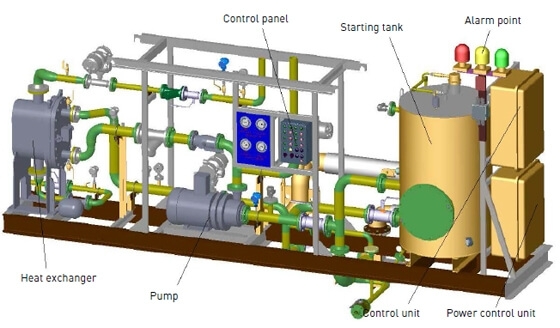

2. Common for several railway cars Reheating and Unloading system (several railway cars are handled by one unit that includes certain number of unloading arms and single common pump, heat exchanger, control system, etc.)

More over, depending on customer’s preferences our systems could be equipped with either top or bottom unloading arms, or both, to allow easy and fast unloading even in cases when one of the tanks hatches is jammed.

Our railway tank unloading systems provide outstanding efficiency, maintain product quality, meet local safety and environmental regulations, and generally provide the most cost-effective, simple to operate, and reliable solutions available.