We offer an extended range of Automatic Samplers and auxiliary equipment, which were originally designed and tested in cooperation with British Petroleum. Offered Sampling solutions comply requirements of the latest revisions of ISO 3171 and relevant API and IP industry standards. Maurer™ products have enjoyed an enviable worldwide reputation for engineering excellence and long term reliability, with instruments first installed over 30 years ago still providing dependable operation today. Today the Maurer™ product range includes cell samplers, insertion samplers, sample receivers and weigh scales.

Features

- High Repeatability of Grab Volume +/-0.5%.

- Construction of sampler internal non-return valve exit passage avoids separation of immiscible constituents, i.e. water in crude oil during the sampling cycle

- No selective water retention ports within sampler cell

- Stainless steel Construction

- Material selection to meet NACE MR 0715R requirements

- Precision built for precision sampling

- Sampler can be operated at up to 15 grabs/min rate

Purpose

The purpose of a Sampling System is to periodically extract a representative sample from a flowing fluid stream in order to determine its constituent properties. In the case of a two phase fluid stream, the Sampler and the associated collection system must take into account the relative proportions of the immiscible constituents, i.e. water in crude oil, and avoid the 'biasing' of the sample in favor of a particular constituent.

Where dissolved high vapor pressure fractions are also present and these are also subject to determination, the Sample and the associated Sample Collection System must ensure that these fractions are retained during the sampling and storage cycle.

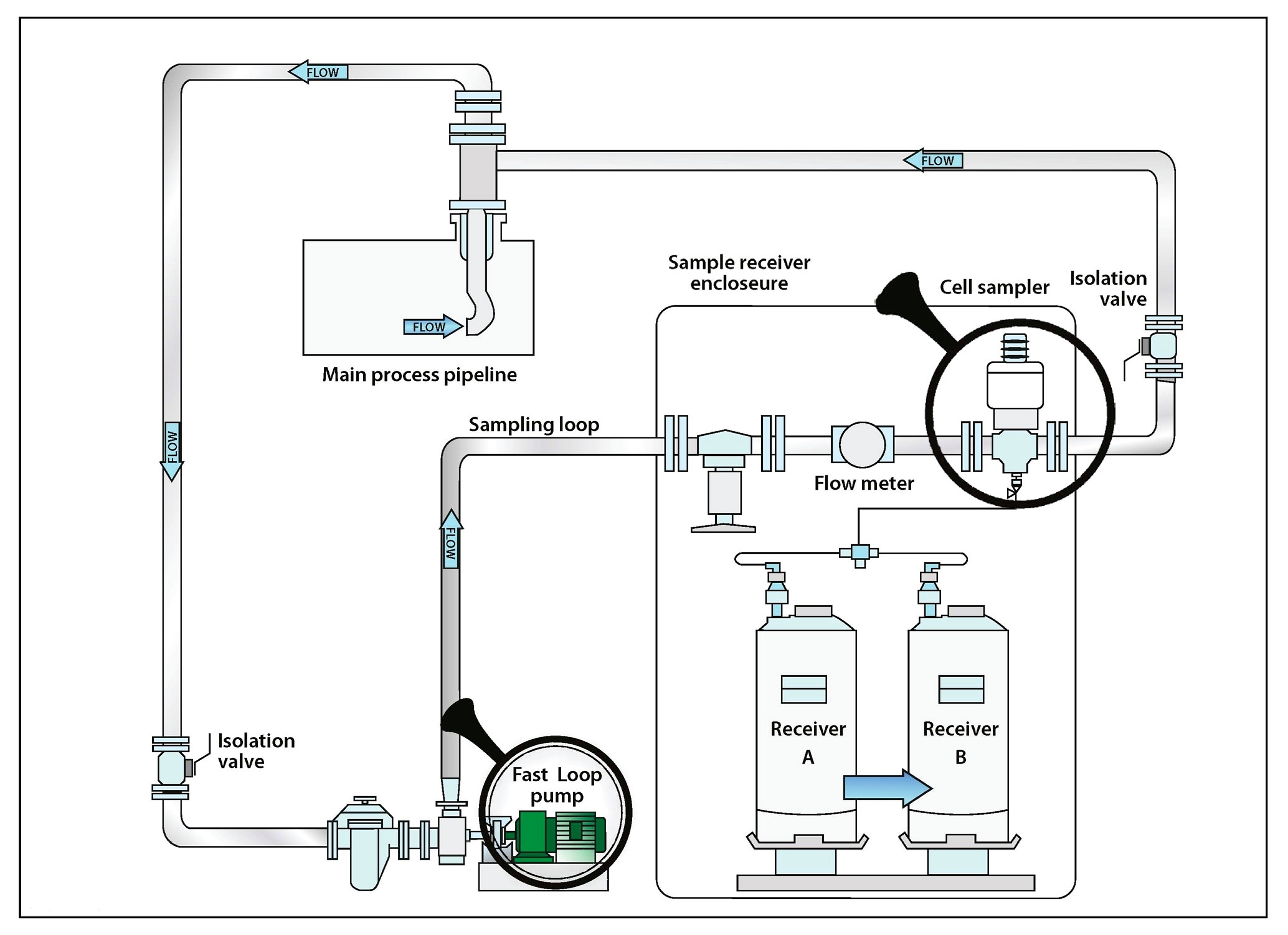

By-pass Sampling

This method of sampling is often preferred for high pressure pipe lines in that the Sampler Cell and its associated flow control equipment can be readily isolated for servicing.

In order to avoid disturbing the relative proportions of any immiscible constituents, i.e. water droplets in crude oil, the flow velocity into the chamfered mouthpiece of the scoop tube should be the same as the average velocity of the bulk fluid, i.e. sampling should be carried out under isokinetic conditions. Thus the scoop tube, pump and, where applicable, the by-pass flow regulating means, should be carefully sized.

For accurate sampling, the fluid entering the scoop tube should be representative of the bulk fluid in the pipe line.

How it works

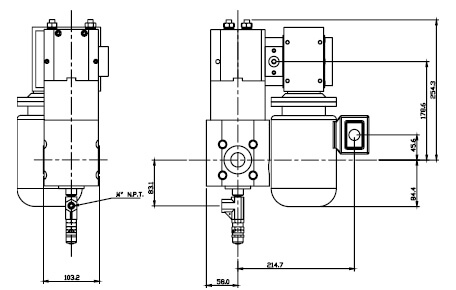

Basically Automatic Sampler is an electrically actuated precision metering pump. The sample extraction facility consists of a tubular stem with an inner concentric capture tube and a piston. Each sampling cycle is a 3-step Sampling Action:

- Piston and Capture tube in fully up position. Sample flows through chamber. NRV closed.

- Capture tube descends to trap sample volume. Piston remains up and NRV is still closed.

- Piston (with capture tube) descends to expel captured sample through NRV to sample receiver.

For operation Electric Sampler requires additional electrical control box.

Depending on particular application requirements Electric Sampler can grab samples on time basis or proportionally to actual flowrate. Controlled by flow computer Electric Sampler grabs from 1 000 to 10 000 grabs per batch, in order to provide representative sample for further laboratory analysis.