Helical Turbine Flowmeters

Are meant specifically for high class metering of crude oil and refined products.

Turbine meters

Are renowned for their reliability and unmatchable accuracy in fiscal metering applications such as:

- FSO & FPSO custody transfer (crude oil)

- On and Offshore allocation metering (crude oil, condensates)

- Pipeline metering stations (crude oil, refined products)

- Tanker loading/offloading terminals (crude oil, refined products, petrochemicals)

- Storage management (crude oil, refined products, petrochemicals)

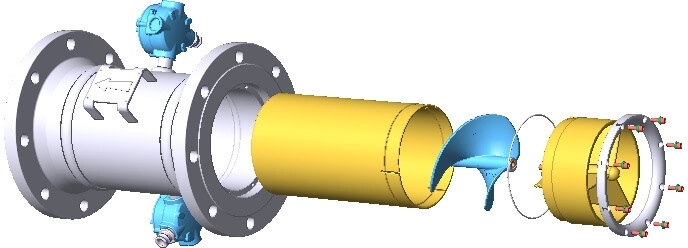

The heart of the Turbine Flowmeter is helically shaped rotor which rotates and its rotation frequency proportionate to current flow rate. Edges of the rotor blades have embedded magnets that generate signals / pulses in 2 sensors, installed on the body of the flowmeter, every time these magnets pass by.

Helical blade is installed inside extractable stainless steel cartridge and supported by 2 robust cross pieces equipped with wear-resistant tungsten carbide bearings. The whole cartridge is contained inside the body of the flowmeter and securely fixed inside by means of a locking ring.

Each pulse emitted by the transducers equals certain amount of fluid, which passes through the flowmeter. This governing principle determines operating and proving/calibration methods of turbine flowmeters. The number of pulses which corresponds certain fixed volume of particular fluid is called K-factor. This figure is the key parameter for flow measurement and it varies, depending on a size of particular flowmeter and application media properties.

The most important advantage of Helical Blade Turbine flowmeters in comparison with conventional type multi-blade turbine flowmeters is that their accuracy and stable performance do not depend on actual viscosity of the fluid. This feature allows using Helical Blade Turbine meters in applications where operating viscosity is constantly changing.

Advantages of Helical Turbine Meters

- Unmatched repeatable accuracy

- Wide dynamic range of flowrates

- Rotor blade made of special light alloy or titanium successfully resists any kind of corrosion

- Curved shape of the Helical rotor prevents fibers and sludge from sticking to it, and thus guarantees reliable operation

- Tungsten carbide bearings are designed and located in a way to allow passing fluid to properly wash and clean them

- Replaceable cartridge made of stainless steel guarantees simple servicing and minimum operation interruptions for maintenance purposes

- Custom materials can be applied such as Titanium, Inconel, Duplex etc.

- Reduced pressure drop in comparison with other type of flowmeters used for Custody Transfer operations

- NONsensitivity to viscosity variations. Wide fluid viscosity ranges can be covered with a single meter factor without recalibration.